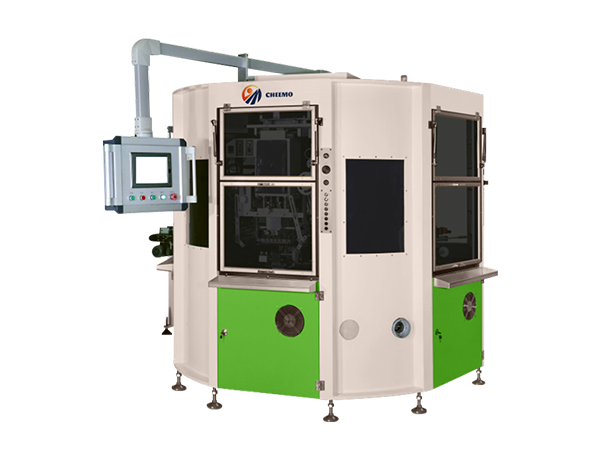

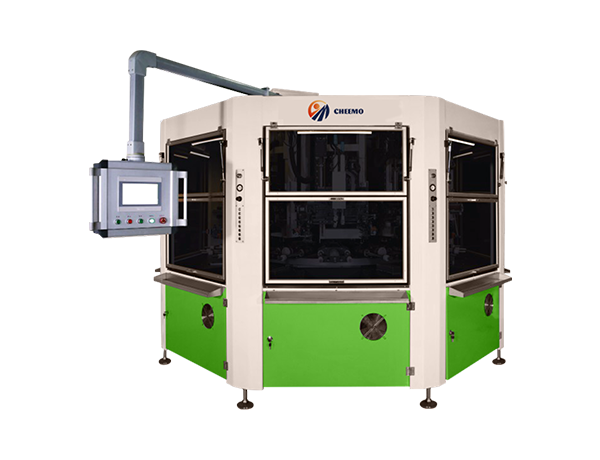

Adhering to the scientific design concept of "intelligent, customized, high quality, high efficiency" , Cheemo takes technology research,development and brand operation as the core competitiveness, and provides energy-saving and environmental protection non-standard customized solutions for the industry system.

With 16 years of experiences in screen printing and continuous research and development, we have a complete series of automatic screen printing system equipment for glass and ceramic bottles of different shapes of packaging containers, fully meeting the personalized needs of the beverage industry. Cheemo equipment provide easy-to-use interface that can quickly set 360° printing, up to 10 colors.

Cheemo's professional operation team can provide one-stop solutions such as professional design and multi-color screen printing and provide professional packaging container printing services for pharmaceutical manufacturers. Meanwhile Cheemo provide customers with related overall service solutions.

Cheemo's spirit of continuous innovation drives us to seek more and more high-performance solutions, to achieve visual CCD positioning printing quality and new printing concept. Through the complex multi-color process or multi-color separation of high requirements of trademark clear pattern level, to achieve unprecedented multi-color printing.

In daily plastic container industry, we have been able to rely on a wide range of combinations, with dry offset machines combined with up and downline accessories such as: glazing, painting, tracing machines, on-head printing, etc, able to satisfy the various needs of users.

We can provide a one-stop solution for professional design of 360 degree curved elliptical, octagonal, fox shaped, semi circular and other screen printing.